Contents

A correct gas spring is an integral part of checking the performance and durability of your application. It doesn’t mean that you have to spend a lot on them. But you need to spend wisely on them. There is a huge variety of struts available in the market which are used for a lot of purposes. Head over to Ovesco if you’d like to know more about gas struts and hardware supplies. They are selected to perfectly suit your needs by understanding the requirement level.

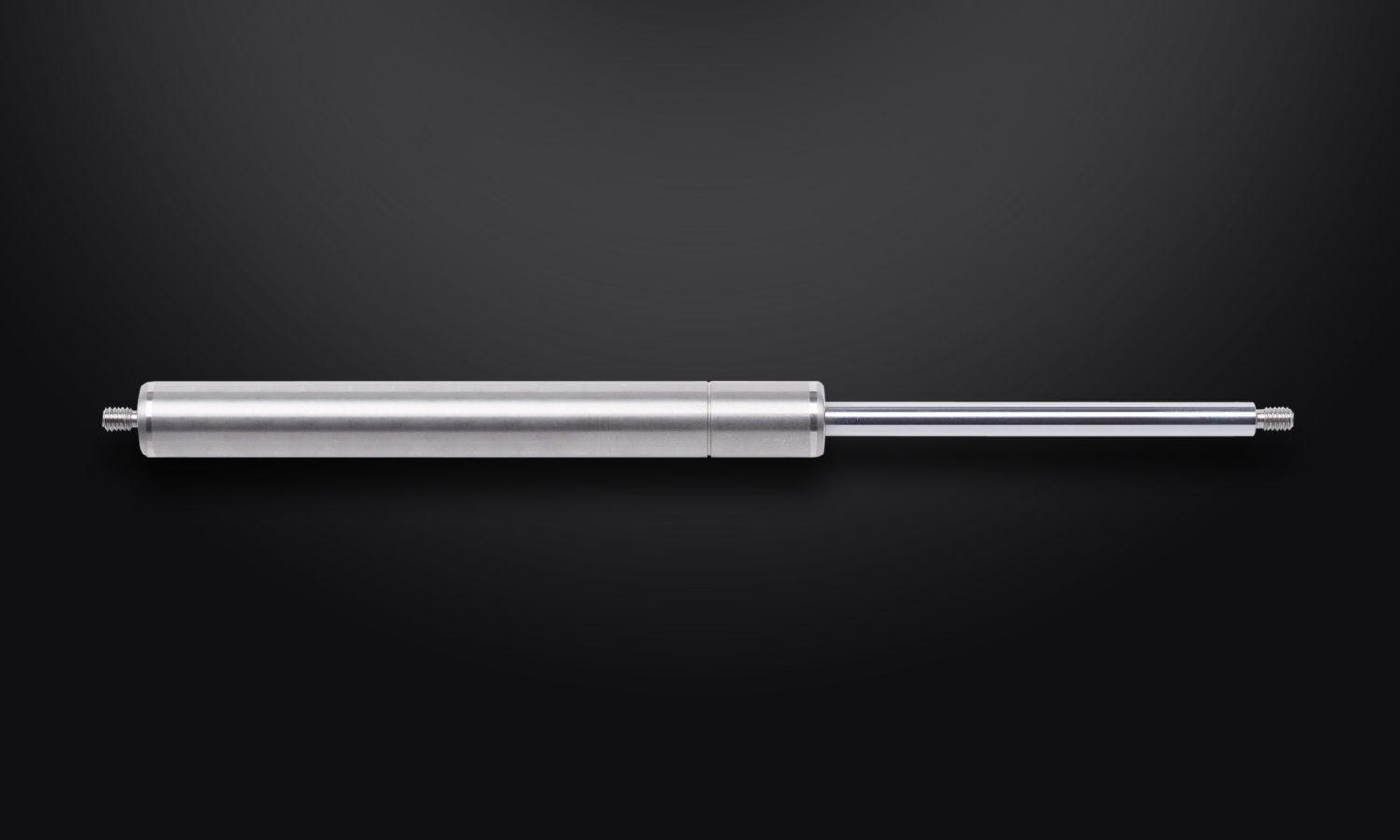

What is a gas strut?

Gas strut is like the gas shock which provides important support for lifting, lowering positioning and counterbalancing different weights and mechanisms. They are useful for inviting a range of industrial applications to commercial vehicles in event machine guard enclosures. They are even useful in agriculture equipment and karavans.

They are generally charged with inert nitrogen gas with rod pushing that reduces the gas spring. The pressure increase in compression of gas creates a spring that behaves with resistance to force. The path for the piston enables proper flow by controlling the speed of the spring to an extended length. You can even make them customers according to your requirements.

Types of gas struts

There are a lot of different struts available in the market, some of them are useful for your requirements while some are used for other purposes. They should be high-speed extensions and low friction to meet the specific requirements.

Standard fixed force

Standard fixed force is a popular type of strut that is available in different sizes and force choices. From end connector to bracket everything is there in this type of strut. They are adjustable to any force according to the range and are not required to calculate force. You can charge maximum force and even adjust it after installation. They have simple adjustments with the help of standard tools. They are the best ones for prototyping and production runs. They are even helpful in a variety of weight applications available in stainless steel.

Vari lift

They are one of the most adjustable gas struts designed for easy degassing. Low volume application and require less force to run. They are useful in prototyping and new applications. They can be adjustable to force in any range without calculating it. The charge is maximum during manufacturing and adjusted after installation. The case can also be released gradually at the end of the tube with simple reasonable adjustment. They are also useful in a variety of weights and short production runs. They also use stainless steel.

Econoloc

It is one of the most important gas springs for safety locking purposes. It can automatically engage in extension properly to prevent spring compression. It also protects against potential injury during overload or misuse of gas pressure. A self-contained and easy-to-use strut.

Conclusion

The wide variety and use of struts make them perfect options for various industries. These three types are commonly used while others are used according to the individual application.